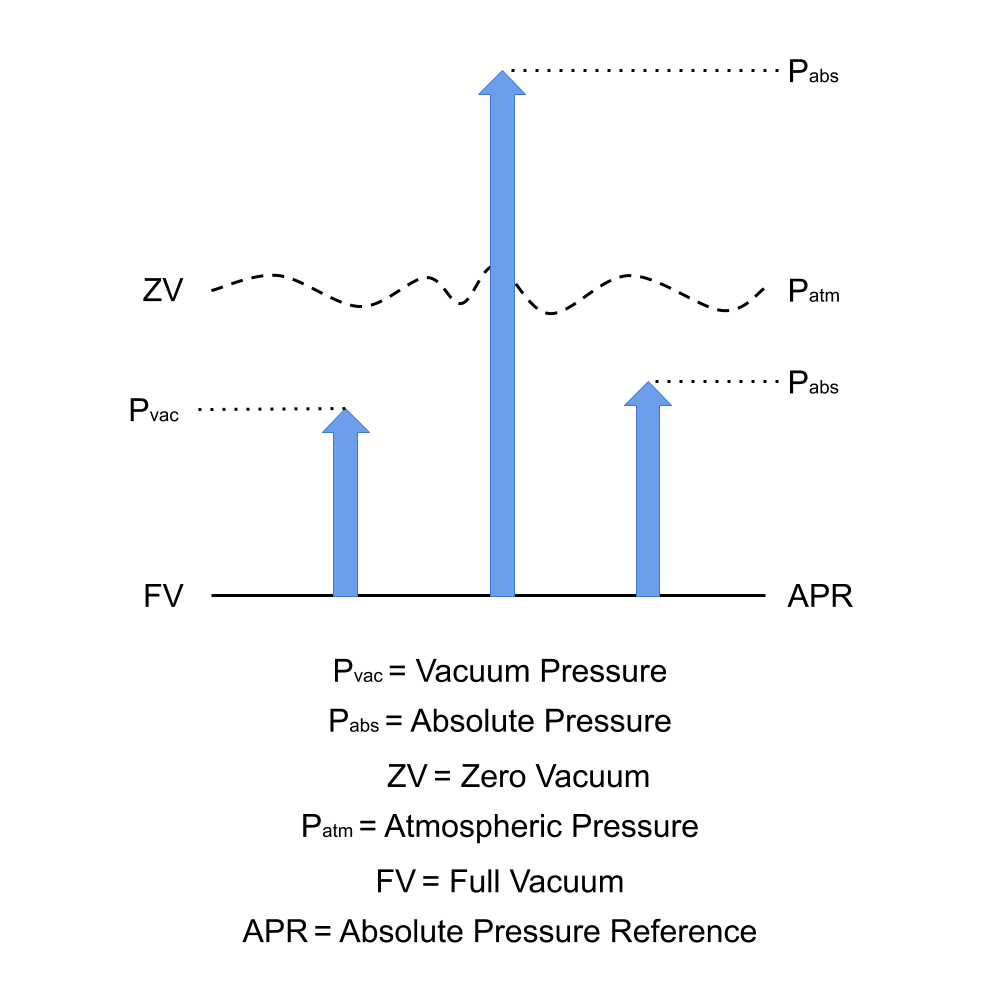

A vacuum pressure is one that is lower than the surroundings environment pressure, and is usually measured comparative to a perfect vacuum or full vacuum. Since the reference pressure is not comparable to another pressure and does not change, it is called the absolute reference or absolute pressure reference.

What is absolute pressure?

Any pressure measured respective to a full vacuum, whether below or above the ambient air pressure, is called an absolute pressure.

A vacuum pressure can be defined and measured as an absolute pressure, but an absolute pressure can also be used to define pressures which are outside the vacuum range.

How Vacuum Pressure is Measured?

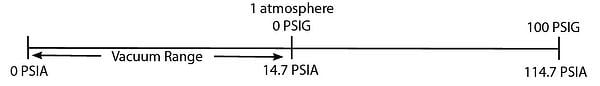

According to definition, vacuum is any space that is partly exhausted by unnatural means (such as an air pump). This concept is referring to a high or hard vacuum. Following figure illustrates that relationship of gauge and absolute pressure with 0 PSIA equal to a high or hard vacuum.

Measurement of Gauge Pressure

Gauge pressure is measured with respect to ambient atmospheric pressure (approximately 14.8 PSIA). It is mentioned to as pounds per square inch (gauge) or PSIG. The electrical output of a gauge pressure accelerometer is 0 VDC at 0 PSIG (14.8 PSIA) and full scale output (typically 5 VDC) at full scale pressure (in PSIG).

Measurement of Absolute Pressure

Absolute pressure is measured comparative to high vacuum (0 PSIA). It is mentioned to as pounds per square inch (absolute) or PSIA. The electrical output of an absolute pressure transducer is zero(0) VDC at zero(0) PSIA and full scale output (typically 5 VDC) at full scale pressure (in PSIA).

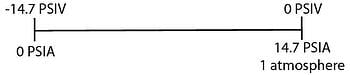

Vacuum can make reference to any pressure between 0 PSIA and 14.8 PSIA and hence must be further explained. For applications linked with measuring vacuum pressures over this full range, two different approaches are frequently taken.

Vacuum pressure is measured with respect to surroundings atmospheric pressure. It is mentioned to as pounds per square inch (vacuum) or PSIV. The electrical output of a vacuum pressure transducer is 0 VDC at 0 PSIV (14.8 PSIA) and full scale output (typically 5 VDC) at full scale vacuum, 14.8 (0 PSIA).

The vacuum pressure transducer provides an increased positive voltage output corresponding to decreasing pressure (increasing vacuum). The absolute pressure accelerometer gives an increased positive voltage output proportional to increasing pressure (decreasing vacuum).

For Example

Vacuum Transducer

Range: 0 to 14.8 PSIV

Output: 0 to 5 VDC

Absolute Transducer

Range: 0 to 14.8 PSIA

Output: 0 to 5 VDC

Differential Pressure

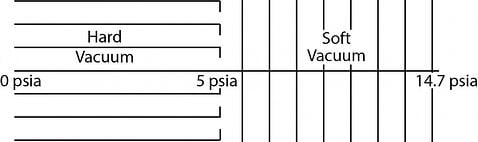

Vacuum is also referred to as negative pressure (or soft vacuum). This happens when the application needs observing both decreases in pressure below atmospheric pressure and increases in pressure above atmospheric bidirectional differential pressure.

differential pressure is pressure measured comparative to a reference pressure. It is referred to as pounds per square inch (differential) or PSID. If the reference pressure is 1 atmosphere the differential pressure range is equal to gauge pressure range. The electrical output of a bidirectional differential pressure transducer is 0 VDC at 1 atmosphere with increased positive voltage output corresponding to increased positive pressure and increased negative voltage output proportional to increased negative pressure.

Example

Bidirectional Differential Pressure Transducer

Range: 0 to ±5 PSID

Output: 0 to ±2.4 VDC

Bidirectional differential pressure transducers are used for low or soft vacuum measurements (typically greater than 5 PSIA) while low absolute pressure transducers are used for hard or high vacuum measurements (generally less than 5 PSIA).

Setra’s Vacuum Sensors

Setra’s vacuum pressure transducers are manufactured with capacitances sensing technology and are used in a vast diversity of applications. Stable, accurate, and reliable, Model of Setra 206, 209, and 210 have been successfully integrated into applications from injection shaping to semiconductor manufacturing. The AXD is the innovative addition to this product family and is wanted as a vigorous solution for the most demanding applications.

Vacuum pressure units listed in the ISM Vacuum Unit Conversion Chart

- Standard atmospheres, 760 mm Hg (ATM)

- Pounds per square inch, absolute (PSIA)

- pounds per square inch, gauge(PSIG)

- Torr (millimeters of Mercury)(Torr)

- in Hg (inches of mercury)

- kPa (kilopascals, newton-force per square meter)

- bar (bars, kPa x 100)

- mbar (millibars, bar x 1000)

Note: Measurements of pressure given in inches or millimeters of water, mercury or some other liquid are based on the earliest instrument developed for measuring pressure, the liquid column gauge or manometer.

Factors that affect the consistency and usefulness of relative vacuum measurements

-

Atmospheric or ambient pressure differs with weather

-

Atmospheric or ambient pressure differs with altitude

Tips to remember when evaluating and converting between vacuum units

-

PSI is based on the United States customary system (USCS or USC)

-

Intimate USCS units are the foot, mile, inch, gallon, pound and second

-

US traditional measurements are distinctive to the US but are now defined in terms of metric standards

-

USCS units are broadly used in commercial products made in or sold to the US market

-

The International System of Units (SI), is the current metric system

-

SI is the most commonly used measurement system worldwide

Industrial vacuum systems

Vacuums fall into three domains:

- rough (or coarse), up to 29 in Hg

- middle (or fine), up to 1 micron,

- high, greater than 1 micron.

Almost all industrial vacuum systems are coarse. In fact, most workholding and lifting applications control at vacuum levels of only 12 to 18 in Hg. The reason is this it generally more economical to increase the holding or lifting force by increasing the contact area between the vacuum cup and workpiece than it is to pull a higher vacuum and use the same connection area.

Middle vacuum is commonly used for process applications such as freeze drying, molecular distillation, degassing, and coating operations. High vacuums are commonly used in laboratory devices, such as electron microscopes, particle accelerators, and mass spectrometers.

Summary

A typical vacuum system comprises of a delivery lines, ■■■■■■■■■ and various control valves, switches, filters, and protective devices.

Vacuum pump selection

The first major step in choosing the right vacuum pump is to differentiate application vacuum requirements with the maximum vacuum ratings of commercial pumps. At low levels, there is a broad choice of pumps.

To calculate a vacuum needs of a system, consider all work devices to be driven. The working vacuum of the tools can be examined by calculations based on theoretical data, handbook formulas, catalog information, performance curves, or tests made with prototype systems.

The maximum vacuum rating for a pump is intently expressed for either continuous or intermittent duty cycles, and can be obtained from pump constructor. Because the maximum theoretical vacuum at sea level is 29.91 in Hg, actual pump potentialities are based on and compared to this theoretical value. Depending on the vacuum limit ranges from 28 to 29.6 in Hg or about 94% or 99% of the maximum theoretical value and pump design. For some pump types, the maximum rating of vacuum will be based on this practical upper limit.

Mechanical vacuum pumps

A traditional vacuum pump may be recognized as a compressor that works with its intake below atmospheric pressure and the release at atmospheric pressure. Compressors and vacuum pumps have similar pumping mechanisms. The vacuum pump is simply piped to extract air from a closed container and exhaust to atmosphere, which is just the opposite of what a compressor does. Although the machines have many similarities, two important differences between compression and vacuum pumping actions must be considered in system design.

Temperature reflections are very important when we choose a mechanical vacuum pump because high internal or external heat can mainly influence pump performance and service life. Internal pump temperature is important because as vacuum level increases, less air is present to carry away the heat generated, so the pump must absorb more of the heat. Heavy-duty pumps with cooling systems are frequently essential to high vacuum applications. But light-duty pumps can work at maximum vacuum for short periods of time if there is an sufficient cool-off period between cycles. The pump experiences a total temperature rise as a result of all the heat sources acting on it, internally generated heat plus heat from friction, internal leakage, compression, and external ambient temperature.

Frequently Asked Questions

Following are the frequently asked questions related to the topic vacuum pressure:

1. How much is vacuum pressure?

Vacuum is an air pressure measurement that is less than the atmospheric pressure of earth, about 14.7 psi. According to definition, a perfect vacuum, is a space where all matter has been removed.

2. What is the difference between vacuum and pressure?

A vacuum is considered as any pressure less than the local atmospheric pressure. It is defined as the difference between the nearby atmospheric pressure and the point of measurement. A vacuum is accurately measured with a differential pressure transducer that has one port open to atmosphere.

3. Is 0 bar a vacuum?

The representative absolute pressure range for measuring vacuum pressures is 0 to 1 bar absolute. As long as negative gauge and absolute reference vacuum ranges are measuring the same pressure it is often considered that they are the same measurement carried out in different directions.

4. What is a perfect vacuum in PSI?

In the U.S., the common standard to evaluate rough vacuum is inches of mercury (Hg), which can be measured in two different methods. One method is as Hg gauge (HgV), where the scale starts at 0 Hg (atmospheric pressure) and goes up to 29.91 Hg, which is perfect vacuum.

5. What is Hg in vacuum?

The frequently used unit of vacuum measurement used in North America for widespread vacuum is inches of mercury denoted by "Hg, where (“) refers to linear inches and Hg is the chemical symbol for mercury. The most significant point to know about “Hg is that it is a measurement of differential pressure.

Conclusion

Vacuum pressure is the difference between the absolute pressure and the atmospheric pressure.

Pressure(vac) = pressure(atm) - pressure(abs)

Vacuum gauges typically show this difference as a negative value, but they can be adjusted in different ways. In this example, 0 shows atmospheric pressure:

A chamber with an absolute pressure of 10″ would have a vacuum pressure of 29″ - 10 “= 19″. The gauge is calibrated to show a negative value (which would be -19)

When there are nothing in vacuum chambers, the needles would point to zero. When the chambers are full and thus at atmospheric pressure, the needles would point to 29″. So the gauge represents the absolute pressure. So if the chamber had an absolute pressure of 10″, then the gauge would point to 10.